Cooling Drum

Sizing, Cooling the Product

The cooling drum is a practical device used for both cooling the product and sizing it. This equipment can have one or multiple layers, and its design and construction are tailored to the production materials, especially their temperature.

This equipment has steel punched tunnels in the layers, where the materials cool down at the right speed and time while rotating inside the tunnels, and the operations of granulation and separation of waste and contaminants are carried out simultaneously.

It can be said that the cooling drum complements the vibratory sieve and ensures the granulation and temperature of the product for packaging.

The length and dimensions of the device, the slope, the rotation speed, and the number of layers are directly related to the type, shape, and temperature of the materials, as well as the capacity of the production line.

- Cost-effective

- Cooling installation capability

- Product temperature homogenization with the ambient temperature

- Layered design for space optimization

- Designed based on the type of process and application

- Stainless steel body

- Easy installation

TSPtech offers the best system based on the final product and its temperature, capacity, and process type.

Our Innovations

Similar Products

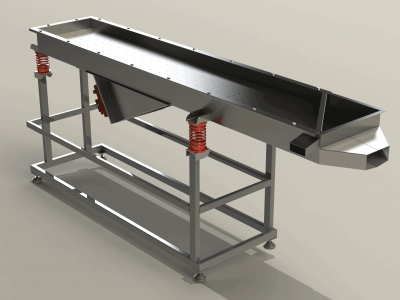

Vibratory sieve machines are used for sizing and separating contaminants or waste materials (such as wood chips, metal, plastic, wire strands, etc.) from the final product.

TSPtech offers the best system tailored to the capacity, type, shape, and dimensions of the product. Read More

TSPtech, with over 10 years of experience in the field, specializes in providing consultation, design, and manufacturing services for all components of single-screw extruders. This includes cylinders, tailored to the type of product, heaters, various cooling systems, temperature regulation, die heads, screen changers, and pelletizers. We are ready to serve you Read More

The TSPtech Lab Blown Film Machine is used for optimizing parameters and testing material dispersion in polymer masterbatches. This equipment, while accurately simulating the process, results in material savings during testing due to minimal consumption of raw materials and reduced waste. Read More

The CTC series hot oil temperature control systems are designed and manufactured for a wide spectrum of high-temperature applications (ranging from 120°C to 260°C). In these systems, the oil flow operates in a closed circuit with low pressure, high flow rates, and comes into contact with electric heaters to achieve optimal heat transfer within the flow. Read More

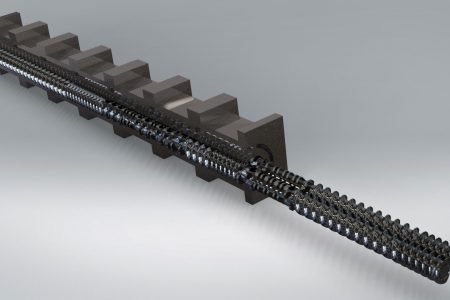

TSPtech specializes in providing consultation, design, and manufacturing services for various components and accessories of twin-screw extruders. Our expertise includes calculating, designing, and fabricating cylinders, thousand-knurled shafts, various segments, dies, breakers, and screen changers in different sizes. Additionally, we offer the best recommendations regarding gearboxes and motors based on specific applications. Our team handles these tasks with professionalism and scientific precision. Read More

The FG series Pulverizer by TSPtech are used for powdering semi-hard, brittle, and impact-resistant materials in processes that require a powdered product. These mills are specifically designed to handle materials that need to be converted into powder form. Read More