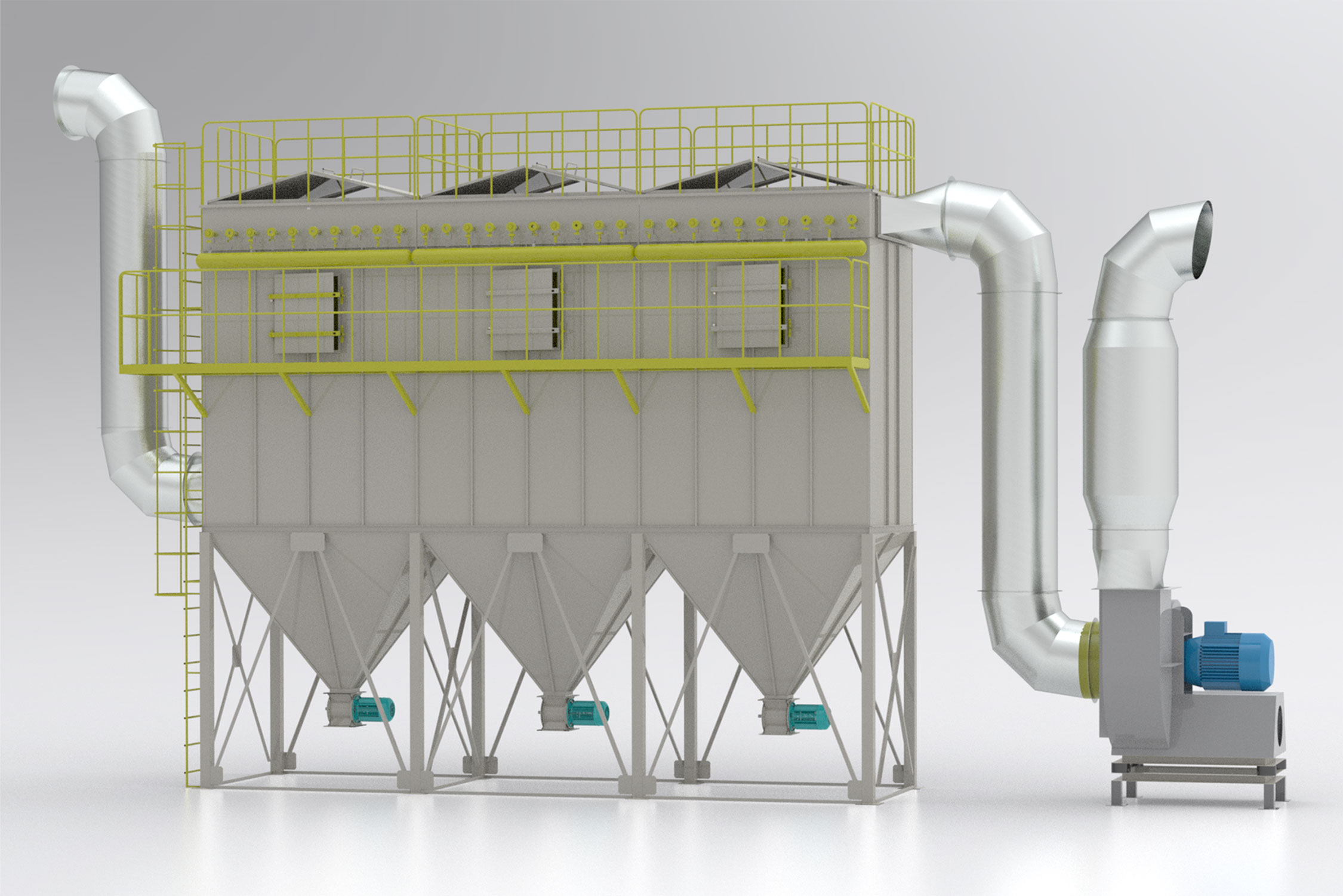

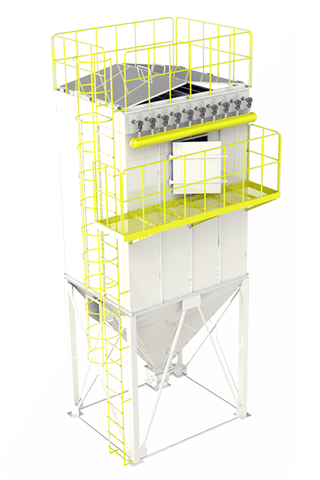

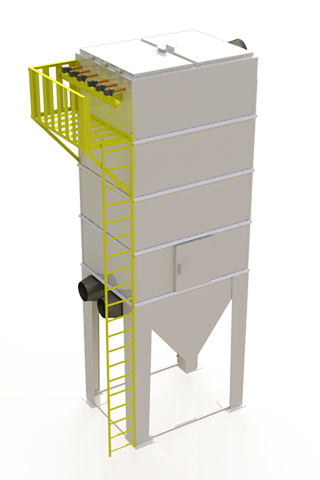

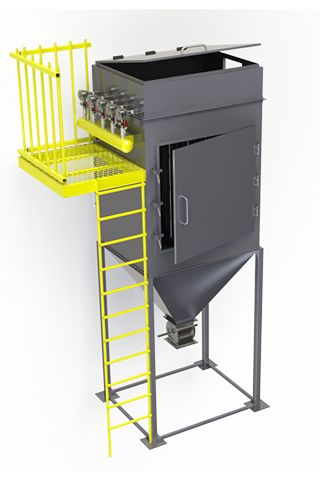

Industrial Dust Collector

Industrial Dust Collector Introduction

An industrial dust collector is a type of air pollution control equipment used in various industrial units.

These devices, through dust and particle filtration, capture suspended particles and harmful fumes generated during the production and manufacturing processes. By preserving and improving the air quality in the work environment and, if possible, recycling valuable dust back into the production cycle, they significantly enhance production efficiency.

The types of pollutants can vary based on the industry. Therefore, the design of dust collection equipment and the methods of filtration and dust collection differ depending on the type of pollutant and its intended use.

The overall purpose and function of these equipment are generally the same

1. Collection of Airborne Pollutants

2. Filtration and Separation of Purified Air from Pollutants

3. Return of Clean Air to the Workplace or Environment

4- Recycling Valuable Dust Back into the Production Cycle

The main components of a dust collection system

1. Fan / Blower

Dust Filter

Dust Filter Cleaning System

4- Dust Collection Receptacle

5- Dust removal system

Common Types of Industrial Dust Collectors

1. Bag Filter (such as jet pulse, vibrating)

2- Inertia Separator (such as cyclones)

3- Cartridge Collectors

4- Wet Scrubber

5- Electrostatic precipitators

The bag filter type dust collector is one of the most common dust collection systems due to its high efficiency.

The type of filter and the filtration area are among the most important parameters for designing and selecting a bag filter system, considering factors such as the type of dust, environmental conditions (including temperature and humidity), and dust volume.

TSPtech designs, manufactures, and implements the most optimal dust collection system based on the type of usage and the conditions of the industrial unit.

The process of presenting solutions by TSPtech

- Dust Examination Using Sampling Method

- Site Visit and Environmental Conditions Assessment

- Consultation, Redesign, Modification, and Optimization of Existing Customer Systems (if possible)

- Design, Construction, and Implementation of a System Suitable for Dust Material, Industry Type, Capacity, and Working Conditions

- Design and Complete Implementation of a Duct System Compatible with the Designed System

- Pre-Delivery Device Testing

- Post-Installation and Commissioning Support

After the Implementation

- Significant Reduction in Existing Pollution Levels in Halls and Improved Production Line Performance

- Capability to Recycle Dust Material Back into the Production Cycle

- Possibility of Using Purified Air for Ventilation in Halls

- Preventing Energy Waste by Recycling Purified Air Back into the Facility

- Cost Savings on Production Consumables

- Enhanced Safety and Efficiency for Workers

Our Innovations

Similar Products

TSPtech with several years of experience in the field of design, construction, and implementation of various dust collection systems, air filtration, and ventilation in industrial factories, provides comprehensive and efficient solutions for industrial ventilation. We achieve high efficiency and low energy consumption coefficients using state-of-the-art equipment. Read More

TSPtech designs, manufactures, and provides consultation for various optimized and unique conveying systems. These systems are tailored to horizontal and vertical distances, capacity, and process type. All the systems we offer are intelligent and user-friendly, engineered by our team of specialists. Read More

The FG series Pulverizer by TSPtech are used for powdering semi-hard, brittle, and impact-resistant materials in processes that require a powdered product. These mills are specifically designed to handle materials that need to be converted into powder form. Read More

Silos dust collectors are used to prevent material loss and also to prevent pollution during the discharge of bulk dry materials into various storage tanks and silos. Our silos’ dust collectors are designed and constructed according to their usage and capacity. Read More

Material dosing systems are used to increase accuracy, reduce labor hours, and overall improve efficiency. We work in the fields of continuous and discontinuous gravitational dosing. It is also possible to implement weighing systems alongside our own transfer systems.

The CTC series hot oil temperature control systems are designed and manufactured for a wide spectrum of high-temperature applications (ranging from 120°C to 260°C). In these systems, the oil flow operates in a closed circuit with low pressure, high flow rates, and comes into contact with electric heaters to achieve optimal heat transfer within the flow. Read More