Pulverizer Machine

FG Series

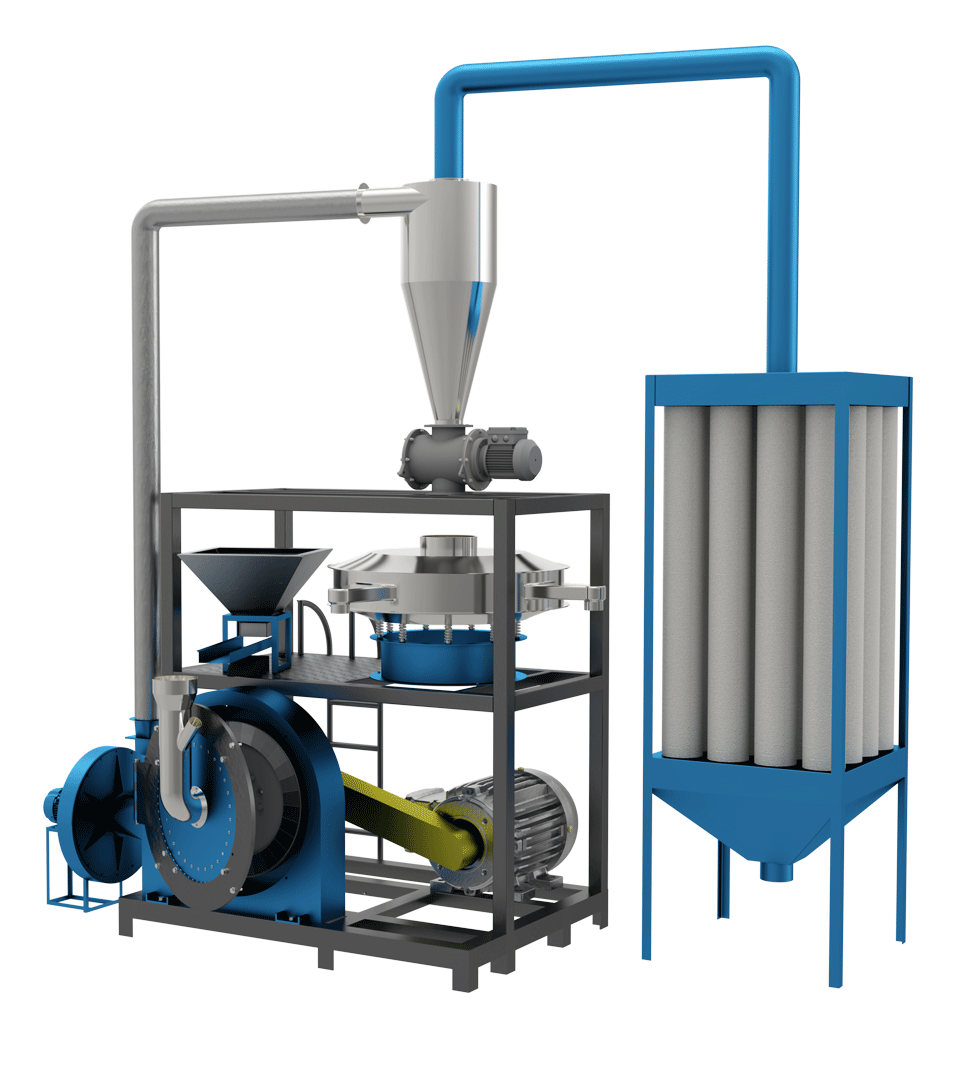

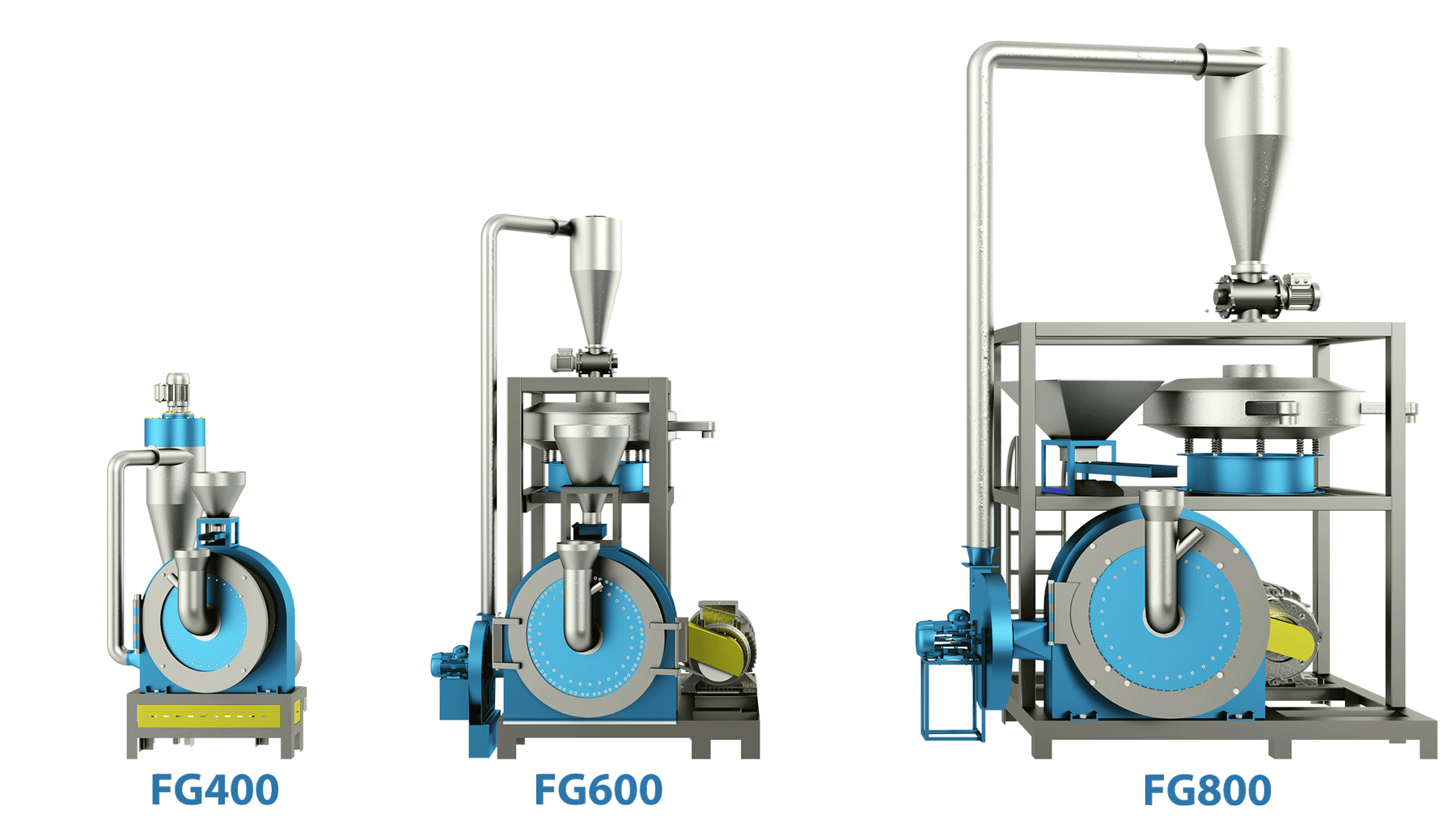

The FG series pulverizer machine by TSPtech are used for pulverizing semi-hard, brittle, and impact-resistant materials in processes that require a powdered product. Granules with a size of 4-9 millimeters are directed into the high-speed rotating blade chamber using a vibratory feeder. Ultimately, the powder produced is transferred by air into the cyclone and cyclone separator. The final powder size can be adjusted by modifying the distance between the blades and replacing the mesh screen.

The high disk speed, small cross-sectional area of the cutting zone, blade design, and an effective process for reducing excess impact ensure that materials are immediately discharged from the powder mill chamber after cutting. This eliminates any additional residence time that could lead to increased temperature. With minimal power, it’s possible to achieve a high output capacity.

Design

- Optimal Layout Design and Space Efficiency

- Applicable for a Wide Range of Materials

- Used for Granule Sizes of 4-9 millimeters

- Designed and Constructed Based on Germany Technology

- Final Output: Powder with Sizes Ranging from 150 to 700 Microns

- Specifically Designed for High-Speed Bearing Seals

ما بر اساس نوع مواد مشتری، ظرفیت و نوع کاربری بهینه ترین سیستم را طراحی و پیشنهاد می دهیم.

Advantages:

- Efficient and cost-effective operations

- Low energy consumption and high output

- Short residence time of materials in the powder-making chamber to effectively reduce thermal stress on the materials

- Easy and fast reinstallation of blades

- Adjustable blade gap from outside the device

- Simple operation, installation, maintenance, and repair

- Use of multi-piece blades to enhance blade lifespan and optimize usage

- Blades made from high-alloy steel (up to 60 Rockwell hardness)

- Reusability of blades for multiple sharpening cycles

- Automatic temperature control

Customization:

The device can be customized in terms of design and construction according to customer needs

Depending on the type of application, it is possible to design and manufacture a disc with specific surface-to-tooth ratio, angle, and diameter. Additionally, we offer high-resistance blades for special applications where wear resistance is crucial.

Based on the type of materials, capacity, and usage, we design and recommend the most optimal system

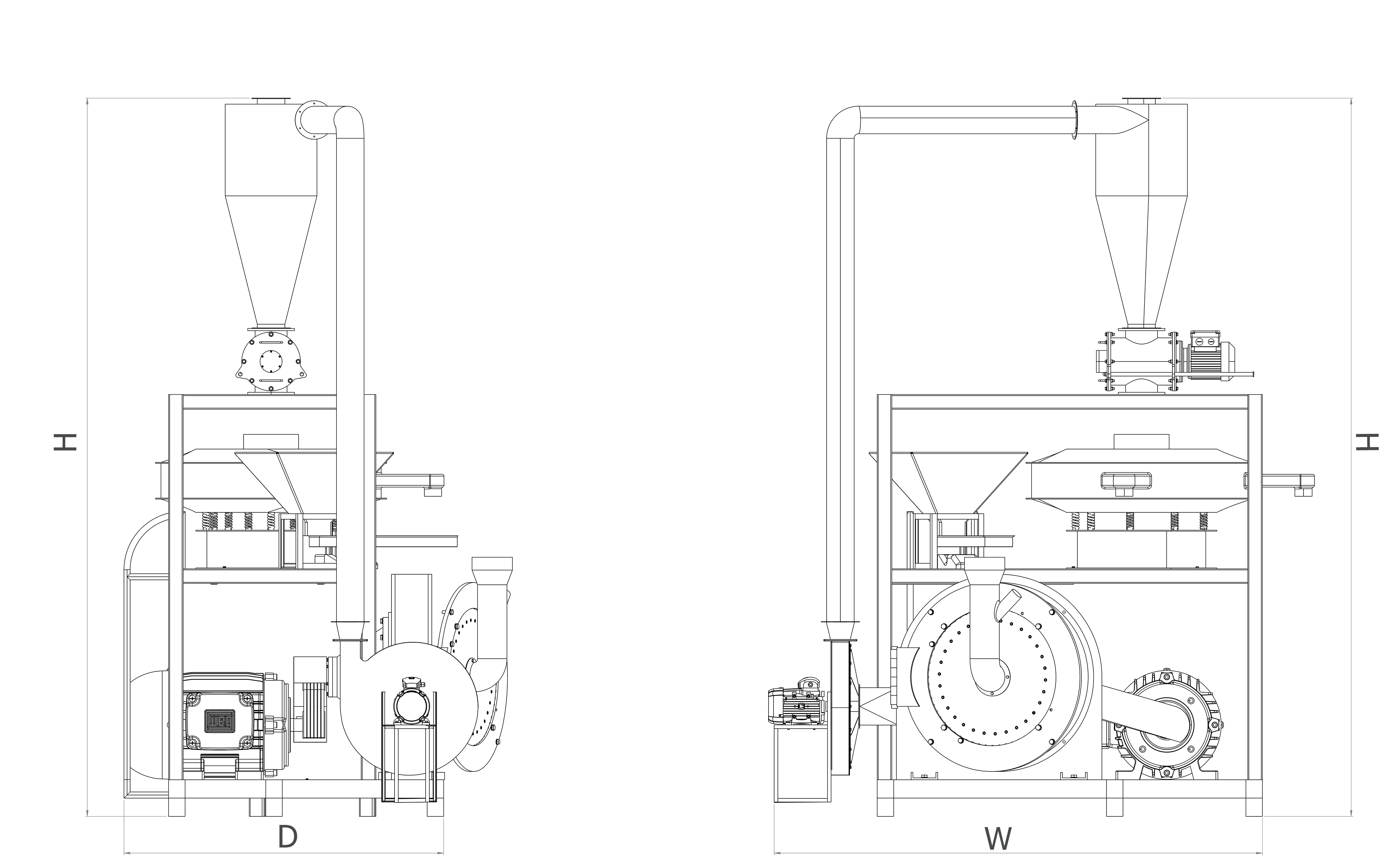

* The size of parameter D has been calculated in the open state of the blade compartment.

* Approximately two square meters of space are required for the dust collector.

* The mentioned dimensions are approximate.

Our Innovations

Similar Products

دستگاه فیلم آزمایشگاهی برای فرآیند بهینه سازی پارامترها و آزمون پراکندگی مواد در مستربچ های پلیمری مورد استفاده قرار می گیرد. دستگاه فیلم آزمایشگاهی طراح صنعت پویا، ضمن شبیه سازی فرآیند با دقت بالا، به دلیل مصرف مواد اولیه کم در هنگام آزمون، باعث صرفه جویی در مصرف مواد اولیه و کاهش ضایعات می گردد. Read More

Certainly! TSPtech provides optimal and unique designs for various transfer systems suitable for horizontal and vertical materials. These systems are tailored to the capacity and type of process. We specialize in manufacturing, implementation, and consultation.

All the systems we offer are intelligent and engineered for ease of use by our expert engineers. Read More

TSPtech with several years of experience in the field of design, construction, and implementation of various dust collection systems, air filtration, and ventilation in industrial factories, provides comprehensive and efficient solutions for industrial ventilation. We achieve high efficiency and low energy consumption coefficients using state-of-the-art equipment. Read More

The CTC series hot oil temperature control systems are designed and manufactured for a wide spectrum of high-temperature applications (ranging from 120°C to 260°C). In these systems, the oil flow operates in a closed circuit with low pressure, high flow rates, and comes into contact with electric heaters to achieve optimal heat transfer within the flow. Read More

Material dosing systems are used to increase accuracy, reduce labor hours, and overall improve efficiency. We work in the fields of continuous and discontinuous gravitational dosing. It is also possible to implement weighing systems alongside our own transfer systems.

These equipment, through dust filtration, capture suspended particles and harmful fumes generated during the production and manufacturing process. They not only preserve and improve the quality of the workplace air and enhance safety but also, whenever possible, recycle valuable dust back into the production cycle, significantly increasing production efficiency. Based on the usage type and industrial unit conditions, we design, manufacture, and implement the best dust collection system. Read More