Dosing System

Material dosing systems are used to increase accuracy, reduce labor hours, and overall improve efficiency. The most common types of these systems are as follows:

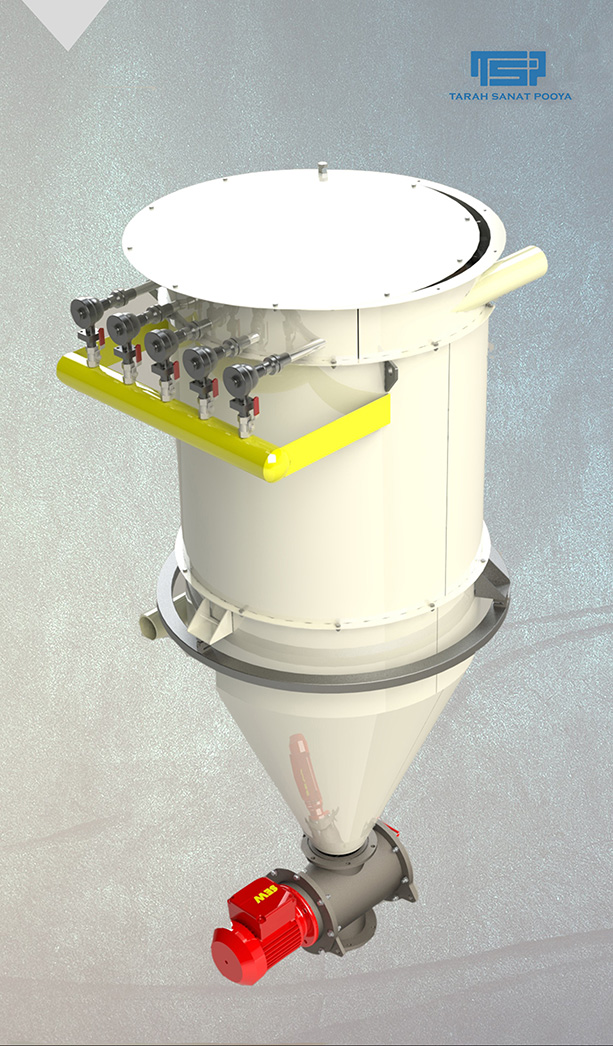

Loss-in-Weight Dosing System

This method is the most complex weighing & Dosing method and is generally used only for solid materials. To implement this system, dynamic equipment is required, meaning that the component being fed must be weighed. However, because the materials are mixed in the subsequent stage, the process becomes complicated.

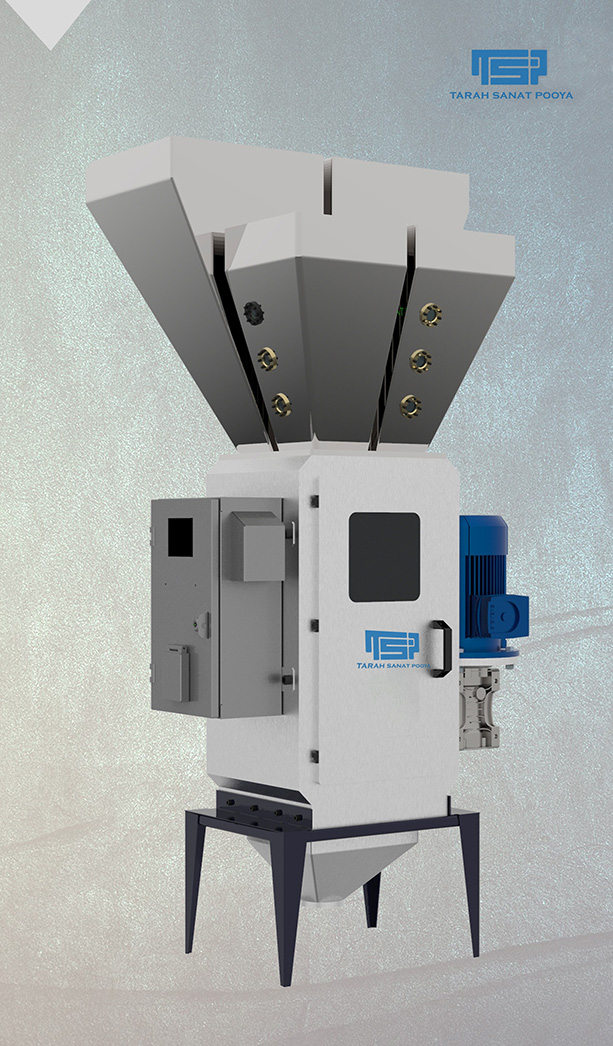

Batch Gravimetric Dosing System

This method is the most common and accurate weighing method. It provides the possibility of weighing in a static state, allowing precise weight adjustment and control.

Continuous Volumetric Dosing System

This type of system is used for both liquids and solids. For liquids, measurement can be highly accurate because density is practically constant. Regarding solids, the volumetric density (bulk density) varies significantly depending on granulometry and the amount of air between particles. Due to the lack of uniformity and non-cohesiveness of materials, this system is only used for systems where the weight ratio of materials is not highly critical or important.

Batch Volumetric Dosing System

This system is similar to continuous volumetric dosing, with the difference that the process is carried out in batches. However, this doesn’t necessarily imply an increase in accuracy. The equipment used in both processes is the same.

TSPtech operates in the fields of loss-in-weight dosing system and batch gravimetric dosing system. Additionally, it has the capability to implement weighing systems along with its own conveying systems.

Our Innovations

Similar Products

TSPtech designs, manufactures, and provides consultation for various optimized and unique conveying systems. These systems are tailored to horizontal and vertical distances, capacity, and process type. All the systems we offer are intelligent and user-friendly, engineered by our team of specialists. Read More

TSPtech with several years of experience in the field of design, construction, and implementation of various dust collection systems, air filtration, and ventilation in industrial factories, provides comprehensive and efficient solutions for industrial ventilation. We achieve high efficiency and low energy consumption coefficients using state-of-the-art equipment. Read More

The FG series Pulverizer by TSPtech are used for powdering semi-hard, brittle, and impact-resistant materials in processes that require a powdered product. These mills are specifically designed to handle materials that need to be converted into powder form. Read More

These equipment, through dust filtration, capture suspended particles and harmful fumes generated during the production and manufacturing processes. They not only preserve and improve the air quality in the work environment but also enhance safety. Whenever possible, valuable dust resulting from the process is returned to the production cycle, significantly increasing production efficiency. Based on the usage and conditions of the industrial unit, we design, manufacture, and implement the best dust collection system.” Read More

Silos dust collectors are used to prevent material loss and also to prevent pollution during the discharge of dry bulk materials into various storage tanks and silos. Our silo dust collectors are designed and manufactured according to usage and capacity requirements. Read More

The CTC series hot oil temperature control systems are designed and manufactured for a wide spectrum of high-temperature applications (ranging from 120°C to 260°C). In these systems, the oil flow operates in a closed circuit with low pressure, high flow rates, and comes into contact with electric heaters to achieve optimal heat transfer within the flow. Read More